Hangar Door Rollers

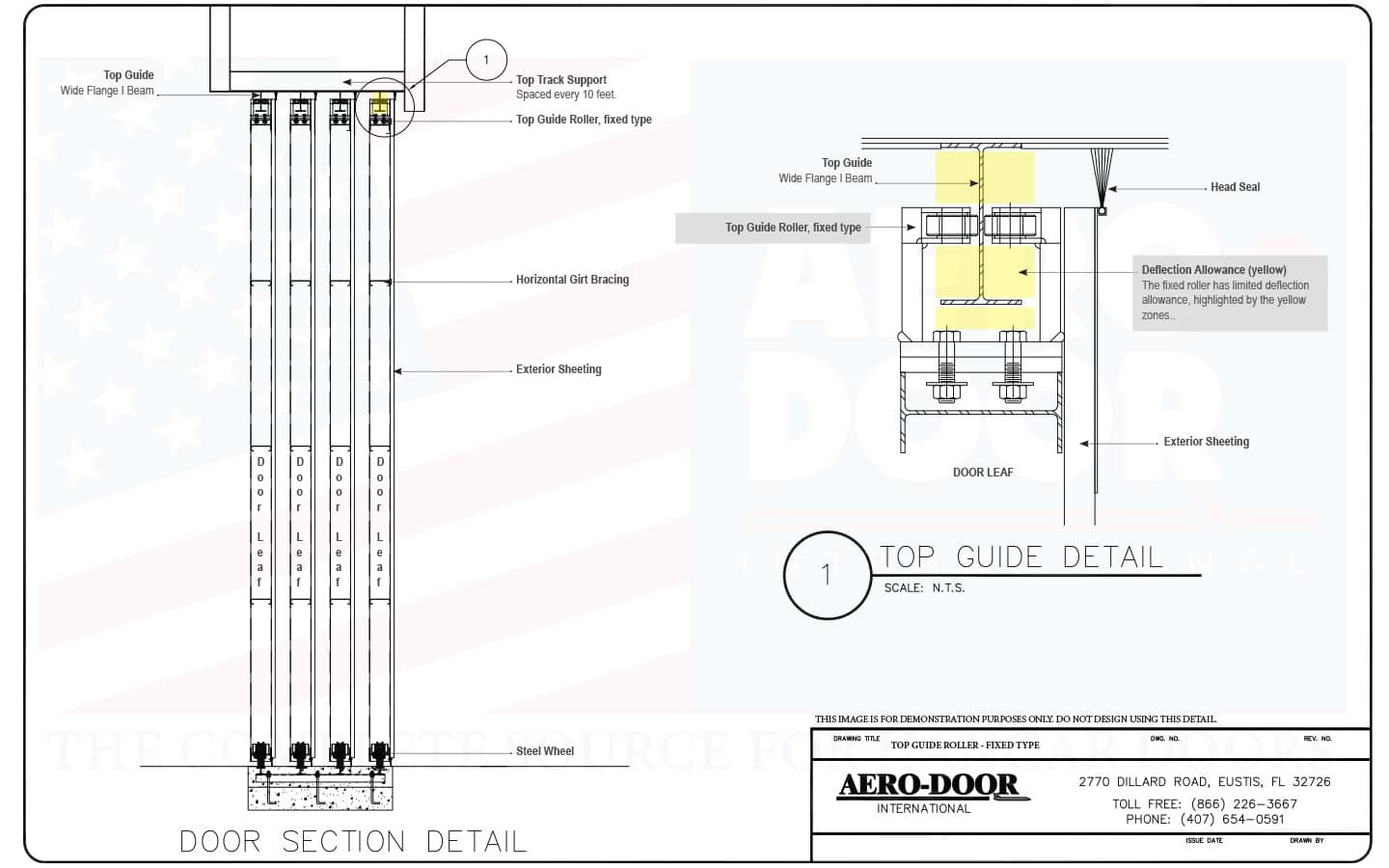

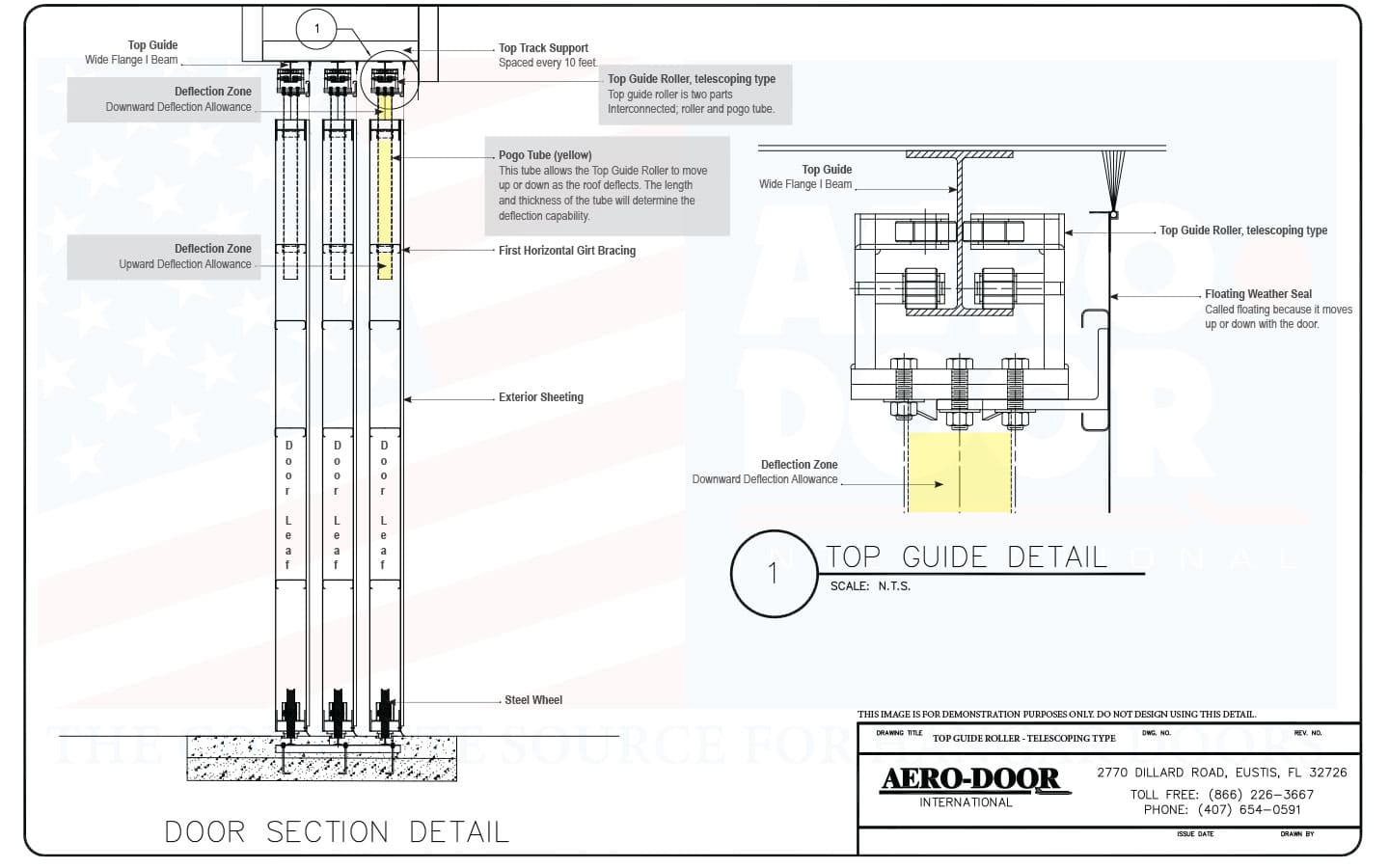

Every hangar door leaf has 2 top guide rollers at the head. The primary job of a roller is to guide the door leaf along the top guide rails but it also defines the deflection capabilities of the door.

When we use the terms wind or live load deflection in horizontal rolling hangar doors we’re talking about how many inches of vertical movement (+/-) a door can tolerate from wind or snow.

There are two types of top guide roller available to choose from and it’s critical the right one is paired for your building.

Here’s what we’re covering in this article:

Fixed Rollers

A fixed roller will be manufactured with a fixed deflection limit. Typically no more than 3-inches total.

If a fixed roller is used in an environment where wind could lift the building roof more than the door roller’s deflection capabilities, the door is at risk of lifting off its bottom rails.

On the other hand, heavy snow loads or downward winds could jam the door in place making it strenuous or impossible to operate.

Telescoping Rollers

A telescoping roller is visually very easy to distinguish because it has a long pogo tube. This tube allows the door rollers to move up or down as the deflection loads of the roofspace change.

These rollers can be designed to wider levels of deflection than a fixed roller, often upwards of 10-inches, making them the most sensible and safest roller for large horizontal rolling doors.

Top Guide Rollers in Summary

The telescoping roller is considerably more expensive than a fixed roller, but will increase the doors live load deflection capabilities. You may also need a floating weather seal which prevents airspace appearing between the head of the door and roller when positive deflection is encountered.

Talk to your building manufacturer about the load limits of the roof space within the hangar door opening. Relay this information back to your hangar door manufacturer and the right choice of top guide roller and deflection capability can be specified.

If you’re retrofitting a door to an existing building structure with no load calculations to determine deflection limits, I recommend you err on the side of caution and use telescoping rollers.

Estimated Market Pricing at time of Article

Fixed Rollers – $550+ per unit

Telescoping Rollers – $1,750+ per unit

Paul has over 14-years of sales and marketing experience in the hangar door industry. Prior to this, Paul spent 8 years working in a sales division of Apple Inc, where skills in supply chain, selling and customer service were taught at a multinational level.