Replacing a hangar door that opens vertically to horizontally

There’s occasions when someone wants to replace a vertical lifting hangar door, such as a bifold or hydraulic door, with a sliding or bottom rolling door which moves horizontally on tracks.

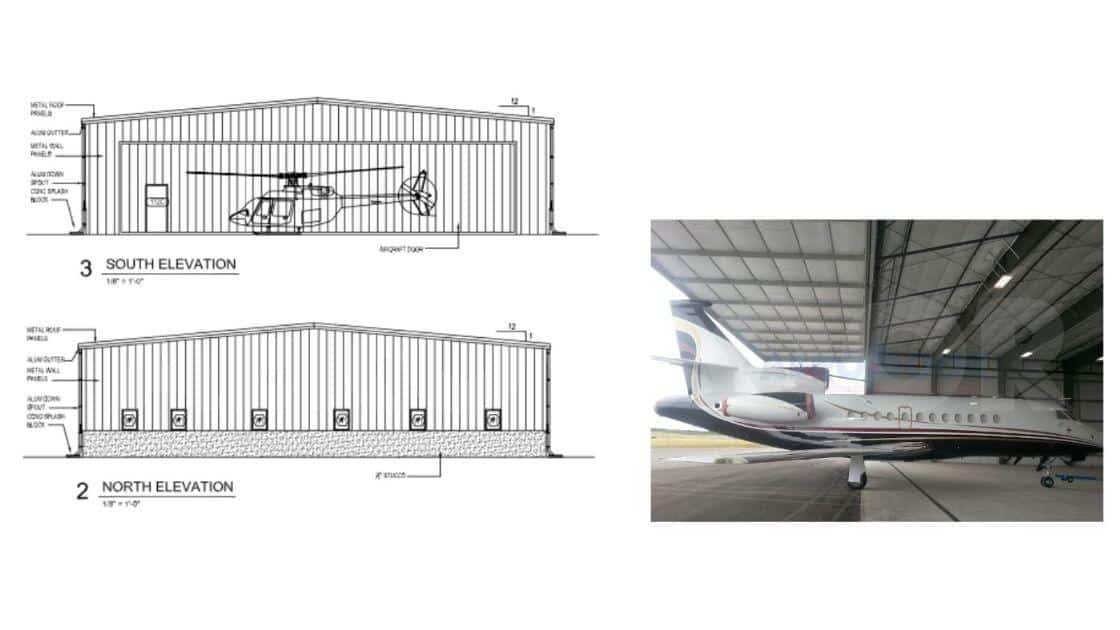

Here we have a typical box hangar with a vertical lift door. There is minimal space each side of the door opening, and the door header is just below the building eave.

The building was probably designed around the loads and forces implied by this particular type of hangar door. Hydraulic and bifold doors impose loads onto the horizontal header and the vertical jamb columns. A horizontal rolling door sends most of the door load into the wheels and the track, but there is a top track that needs to be carried by the building, and wind load is imposed onto that connection point when the door is closed.

2 possible ways to replace a bifold or hydraulic door with a horizontal rolling door

Option 1

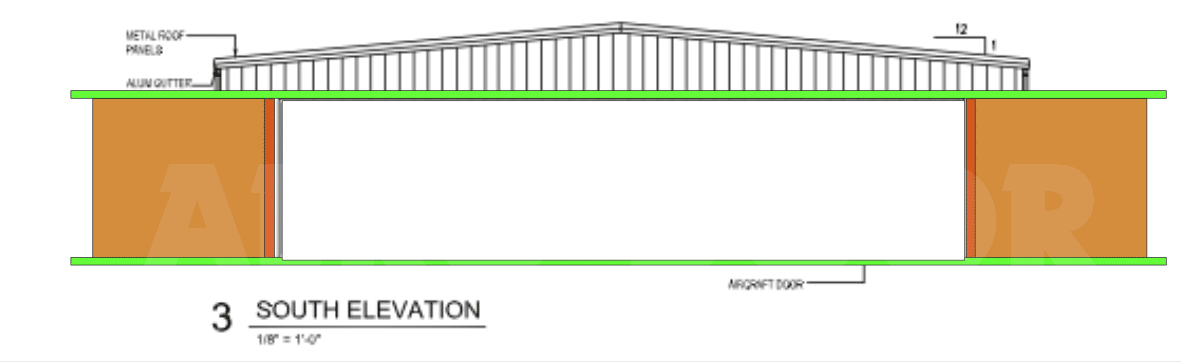

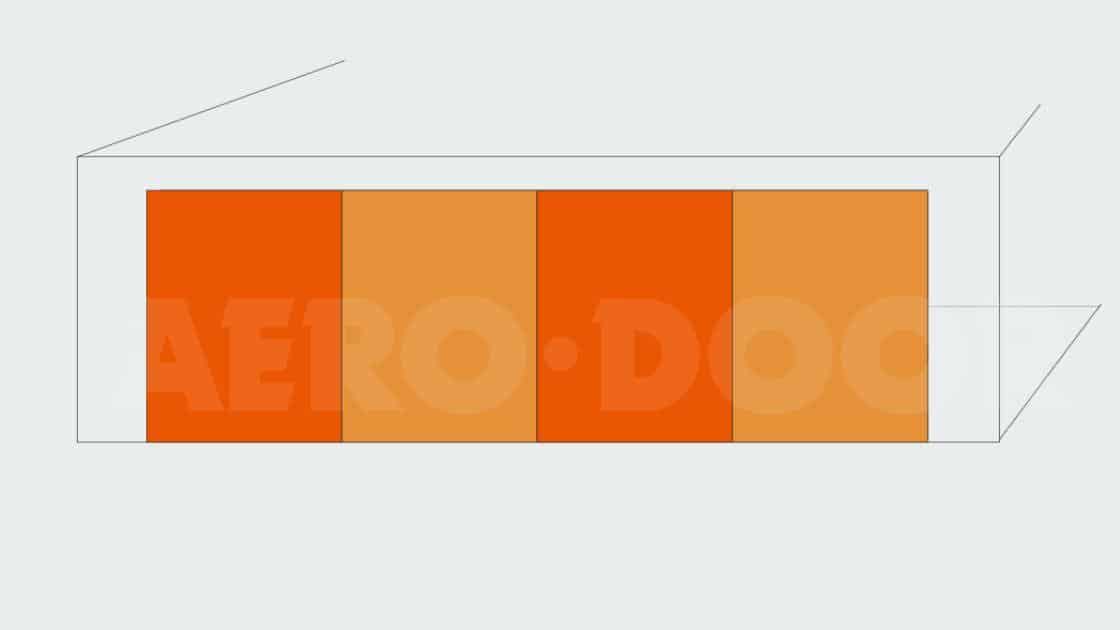

The first choice is to install the horizontal door system to the face of the building structure. The illustration shows a horizontal rolling door that bi-parts in the middle.Two door leaves open right, and 2 two open left. The Green top track and Green bottom rails span the width of the opening, plus extra for the door leaves to be stacked in the open position.

The doors’ horizontal top tracks need to be supported by a steel framework called outriggers. Outriggers become an extension of your building and must be designed to carry the weight and forces that will be implied. That information can be provided by the hangar door manufacturer. Outriggers are not supplied by the hangar door manufacturer.

Option 2

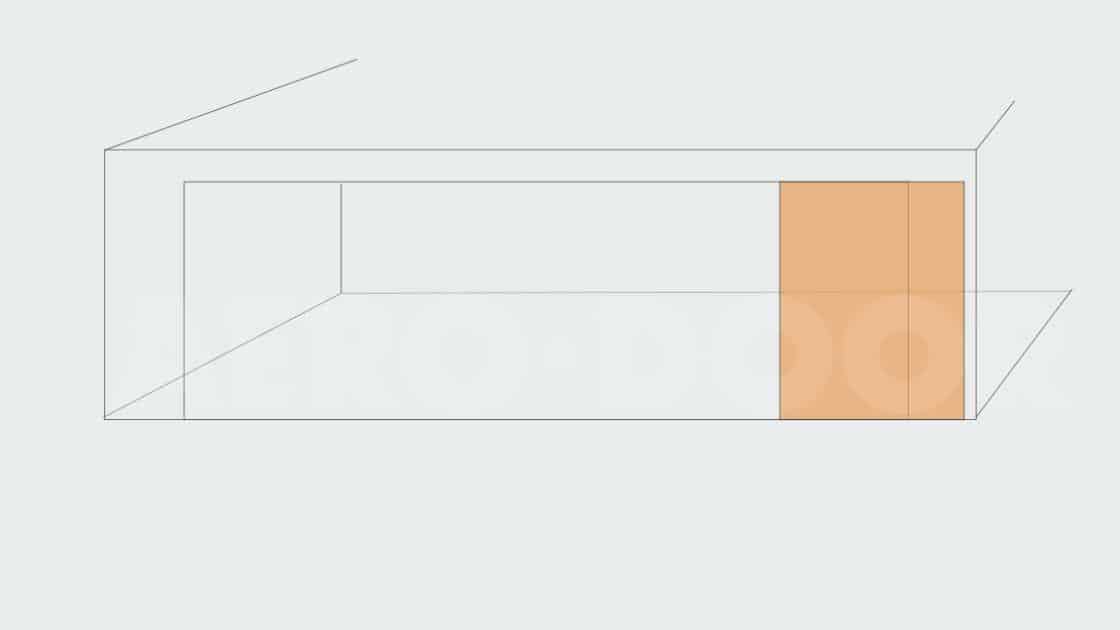

In option two, the door is contained within the building, there are no outriggers. For the purpose of this example I’ve chosen to put 4 door leaves on this opening, and each leaf is on it’s own rail, so there are 4 tracks.

So as the door opens, the leaves slide behind one another, giving you ¾ or 75% clear opening space.

If this was a 100ft wide opening, 75ft clear opening will be adequate for some clients. But let’s shrink this down and assume the opening is only 50ft wide, I dont think offering 75% opening on a 50ft wide opening would be enough for most people. So this idea only works for wider openings.

These panels can be stacked anywhere within the opening space. You can have them manual, or motorized.

We’d probably recommend going as wide as possible with the door tracks, to maximize your clear opening. You can see here the door panels have gone beyond the opening, but still within the building envelope.

AeroDoor can fabricate and install the horizontal door system but you’ll still need to manage how the doors top tracks safely tie back into the building structure. You’ll need to prepare a trench before AeroDoor installers embed the ASCE bottom rail, and then pour the concrete afterwards. You’ll also need to sheet the door leaves towards the end of the refurbishment.

Paul has over 14-years of sales and marketing experience in the hangar door industry. Prior to this, Paul spent 8 years working in a sales division of Apple Inc, where skills in supply chain, selling and customer service were taught at a multinational level.