Types of openers

Motorized hangar doors facilitate operation and makes opening or closing the door an effortless process. Features such as constant pressure switches and sensing edges can also make them smart and safe.

There are two models of door opener on the market, the difference between them is how they move the door, how much space is required, functionality features and price.

Internal door openers

The motor drives a steel wheel also known as the drive wheel. A drive wheel is on the leading edge door leaf. With an internal door opener everything is self contained within the depth of the door frame.

This is an important design feature because it keeps the airspace between the door leaves and the pocket to a minimum. The internal door opener is the preferred choice on a bottom rolling door because it’s sleeker, offers better traction and has a fast disconnect when you need to manually move the door.

Surface mounted openers

The motor drives a pneumatic tire which is in contact with the finished floor. As the motor turns the tire, the door will move.

The surface mount is a great choice up to a certain size and weight of door, as well as a specific range of door configurations. It’s also convenient for hangar doors that are too shallow for the internal motorized hangar door operator.

External operators can be bolted onto most existing doors. This feature makes them a great option for existing hangar doors that presently have no motor.

Internal or surface mounted suitability

The general rule is that:

- Internal door operators can be used on any bottom rolling hangar door leaf that is at least 8-inches deep.

- Surface mounted operators can be used on most biparting or unidirectional configuration that is northern stacking. They are exempt from any explosion proof classification requirements.

The table below shows which door opener can be used for each hangar door configuration. Here is a document outlining each Hangar Door Configuration.

| Biparting Northern Stack | Biparting Southern Stack | Unidirectional Northern Stack | Unidirectional Southern Stack | Floating Group | Independent | |

| Internal Door Operator | Yes | Yes | Yes | Yes | Yes | Yes |

| Surface Mounted Operator | Yes | No | Yes | No | No | No |

Powering your door opener

Look for a hangar door opener that can operate a door at a speed of approximately 45 to 60 feet per minute in zero wind load conditions.The voltage and phase requirements can be designed to the customers requirements but three phase 480V is typical for large bottom rolling hangar doors.

To carry power from the building to the door opener there are two choices:

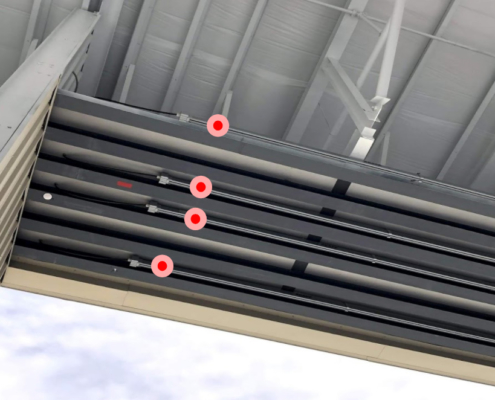

Overhead Trolley Conductor Bar

The overhead conductor has 4 strips of copper that are energized; three for power and one for ground. The conductor bar system spans the width of the doors opening and is fitted between the top guide rails. The system is jointless, meaning drastically less maintenance and money is required compared to a jointed system, and can extend for hundreds of feet, making it the perfect solution for large bottom rolling hangar doors.

SOOW Cable

Often referred to as festoon, this involves draping a cable from the panel with the door opener (drive panel) to each idle panel. It’s been around for decades and is a far more affordable choice, but with that comes limitations. SOOW Cable is not suitable when the door leaves are wider than they are tall because the cable drapes too low, in this instance you will need to use an overhead trolley conductor bar. SOOW Cable has greater potential to need replacing over time because the cable can fray from rubbing against the inside of the door.

SOOW Cable is affordable, popular and does a good job of delivering power. It’s also more suitable on hangars near the ocean where salt can easily corrode a conductor bar.

Motorized hangar doors – Opener features

Most hangar door openers share common features:

- A manual release allows you to disengage the motor from inside the hangar and manually move the door. Great feature when you have lost power to the door.

- Heavy duty mushroom head buttons that require constant pressure to move the door.

- Warning horn that activates during door operation.

In addition, look for other features:

- UL Listed control panel

- NEMA control enclosures with door mounted fused disconnects

- Speed control

- Limit switches that will stop the door opener if a man door isn’t secured

- Variable frequency drive (VFD) for ramp up starting

- Indicator lights

- Heavy duty mushroom head buttons

- Sensing edge support

- Photo eye support

- Class 1 Div 2 explosion proof classification

- Warning beacon during door operation

Safety features

To maximize safety and minimize accidents, consider safety edges for your hangar door. Modern hangar door operators can be designed to stop when the door hits something. Sensing edges are foam filled and include a touch sensitive switch that sends a signal to stop the door opener. A good sensing edge will be 4-wire and have 3.5 inches of over travel.

Here’s an article with more detail about sensing edges.

Look for control panels that require constant pressure on the button to open or close the hangar door. This feature ensures that in an emergency the person operating the door can stop the door by lifting their finger from the button.

Sensing edges are foam filled and include a touch sensitive switch that sends a signal to start, stop or reverse the door opener.

Look for control panels that require constant pressure on the button to open or close the hangar door. This feature ensures that in an emergency the person operating the door can stop the door by lifting their finger from the button.

Summary and takeaways of Motorized Hangar Doors

The right choice of door opener might be decided for you after reading the compatibility and limitation guidelines as explained in this article. As a reminder look at this document which shows the door configurations compatible with the internal and surface mounted door operators.

If your hangar door opening is less than 125ft wide and 30ft tall, then a surface mounted operator will probably suffice for most people. Assuming the door is northern stacking. For doors larger than this an internal door opener is always recommended.

Paul has over 14-years of sales and marketing experience in the hangar door industry. Prior to this, Paul spent 8 years working in a sales division of Apple Inc, where skills in supply chain, selling and customer service were taught at a multinational level.